One very important process for today’s industry is electroplating. It is important both for the aesthetic values it provides, but also for practical reasons. Let’s learn more about it.

- What is electroplating and what is it used in?

- What are the advantages and disadvantages of the electroplating process?

- How does electroplating affect the environment?

What is electroplating and what are its advantages and disadvantages? Let’s find out.

What is electroplating and what is it used in?

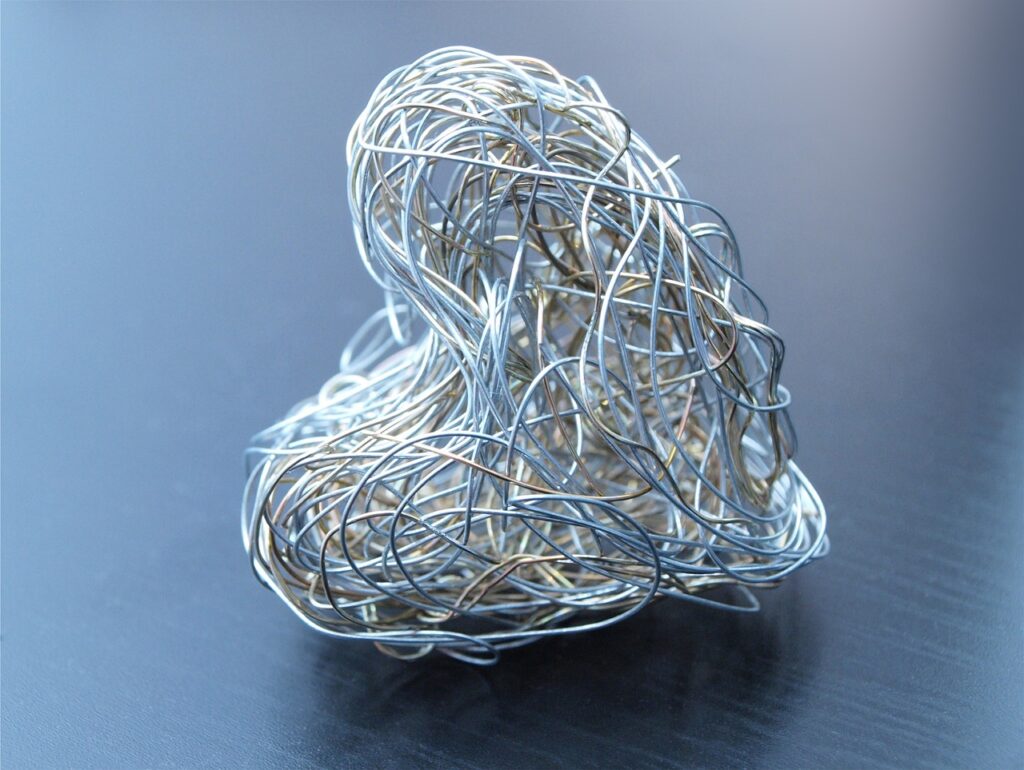

Electroplating is the process of coating with a thin layer of metal such as silver, gold, copper or zinc using an electric current on the surface of the selected material. It is very often combined with other activities, such as varnishing and coating, for example. It is worth noting that this process has great importance in many fields of industry. It is used in medicine, cosmetics, automotive and aerospace industries. More specifically, electroplating is used in the production of a variety of spare parts for the automotive, aerospace or medical industries, in the production of cosmetics, as well as tools of various kinds.

What are the advantages and disadvantages of the electroplating process?

Electroplating is a process that is readily used in the industry because of its many advantages. First of all, it provides high corrosion resistance. Moreover, it increases the durability of the material and enhances surface quality. What’s more, it allows both thin and thick layers of metal to be applied. This means that the process can be tailored to specific needs. Unfortunately, electroplating also has numerous disadvantages. First of all, it is often associated with a very high cost. Moreover, if the process is not carried out properly, it can cause environmental hazards. In addition, it should be noted that electroplating has some limitations in the shape and size of parts.

How does electroplating affect the environment?

Unfortunately, if the process of electroplating is not carried out properly, it can have a negative impact on the environment. For this reason, it is so important to use only responsible companies, where great emphasis is placed on safety and high quality services. It is very important that the water that is part of the electroplating process is properly treated and disposed of. It should also be noted that electroplating can be combined with such processes as material recycling, for example. As a result, this method is not so invasive. Sometimes electroplating can be replaced by other solutions, such as, for example, simple varnishing or coating.